From Idea to Prototype

Everything You Need to Bring Your Product to Life, One Expert Step at a Time.

What’s Included:

- Briefing Session

- Research

- 3 Concepts

- Refined 3D Model

- Renderings with

Color and Texture

Variations

🧠Ideal for:

Entrepreneurs with an

idea but no clear direction or visual plan.

R4000

What’s Included:

- Briefing Session

- Research

- PCB Design

- Design Refinement

and BOM

🧠Ideal for:

Products that include electronic components or IoT features.

💡Note:

This step is only needed for products requiring electronics.

(EXCL. PARTS)

R12000

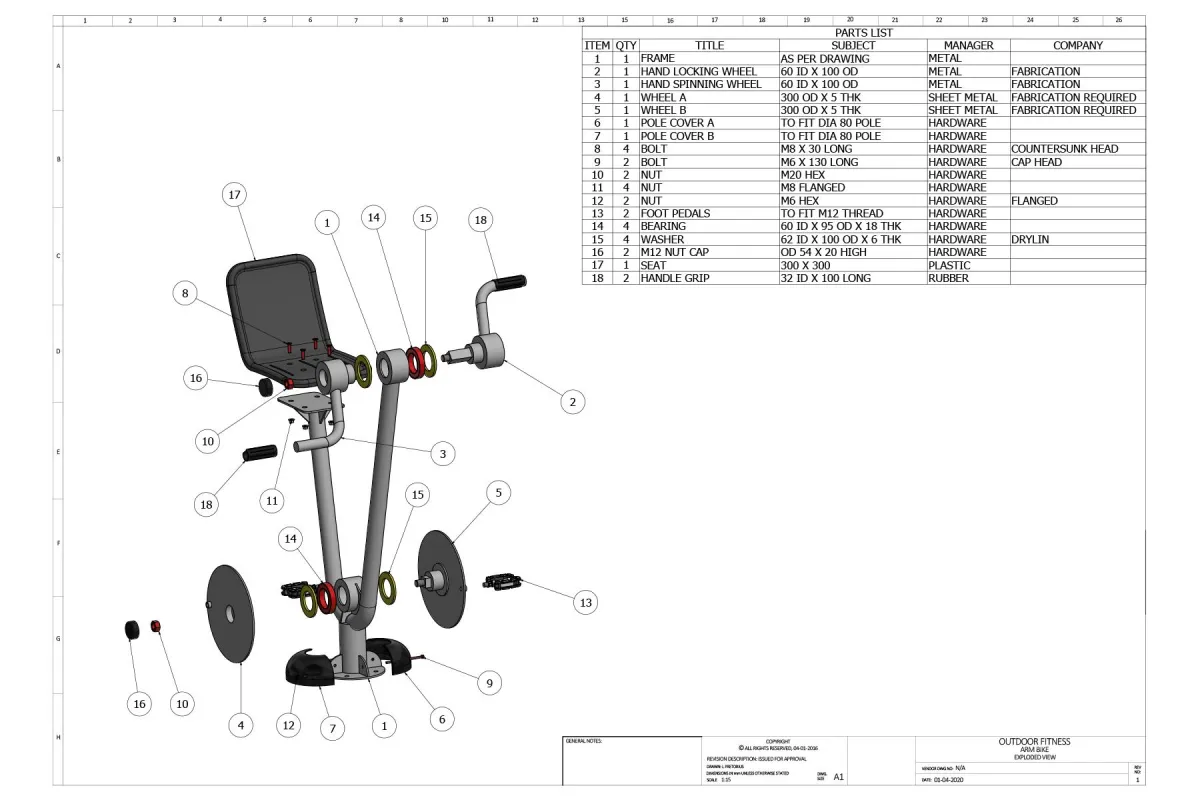

What’s Included:

- Breakdown

of Final Design

- Design for Assembly

(DFA) Strategy

- Engineering of

Components

- 3D CAD Assembly

- Prepare Parts

for Prototyping

- Prototype

Drawing Pack

🧠Ideal for:

Clients ready to move from idea to physical prototype.

R12000

What’s Included:

- Excel-Based BOM

- Supplier Sourcing &

Quote Collection

- Ordering of

Prototype Parts

- Assembly and

Testing

🧠Ideal for:

Clients needing proof-of-concept to present to investors or validate usability.

(EXCL. PARTS)

R6000

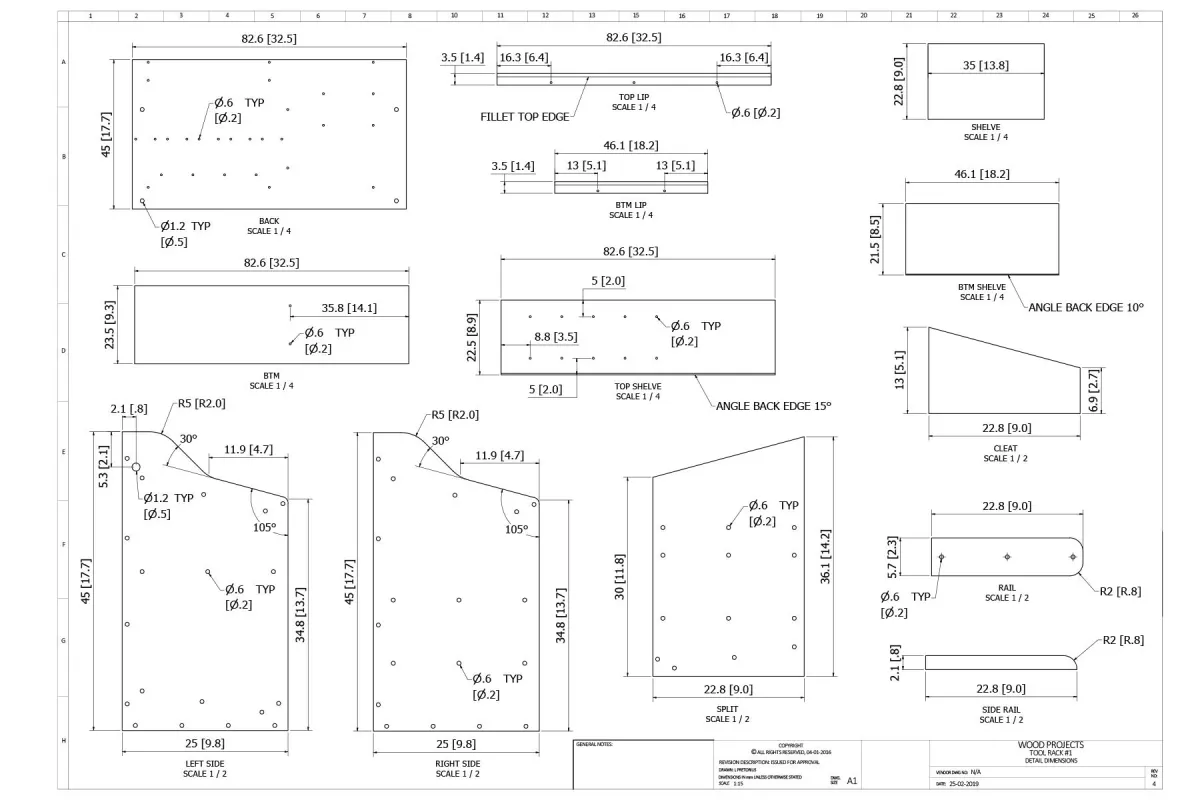

What’s Included:

- Optimized CAD Models

- Full Drawing Pack with

Part BOM & Assembly Instructions

- Manufacturing

Guidelines

- Production Startup

& Support

🧠Ideal for:

Clients preparing to launch, scale, or present to manufacturing partners.

R9000

Your Idea Deserves to Be Real. Let’s Build It.

The only thing standing between your concept and a working prototype is action.

Partner with experts who turn imagination into innovation - one step at a time.

Bring Your Idea to Life!

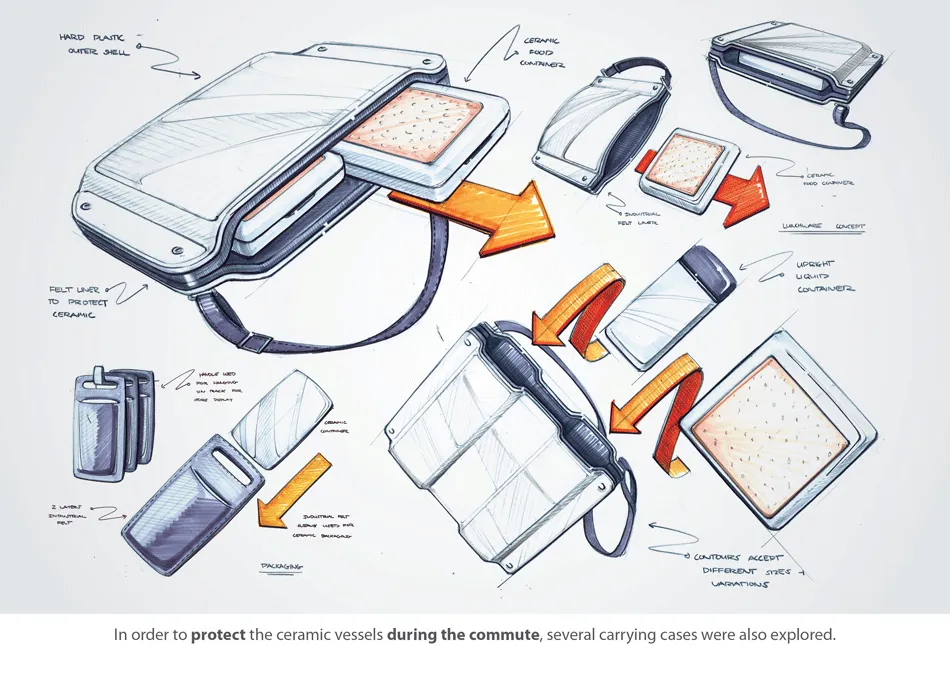

Visually, Clearly, and with Total Confidence

A professionally guided process to refine your idea, visualize it in 3D, and create compelling concept presentations.

You’ve got a brilliant idea—but turning that into something tangible can be overwhelming. Without clarity, your idea stays stuck in sketches or in your head, and you risk going in the wrong direction entirely.

This is where we come in.

In this stage, we help you extract the essence of your idea, explore material and functional possibilities, and develop three unique concept options. Together, we refine one into a stunning 3D model - complete with high-quality renderings so you can see your product in real-

world textures, colors, and finishes.

Whether you're pitching to investors or planning your next move,

Concept Development gives you the visual clarity and strategic foundation you need to move forward.

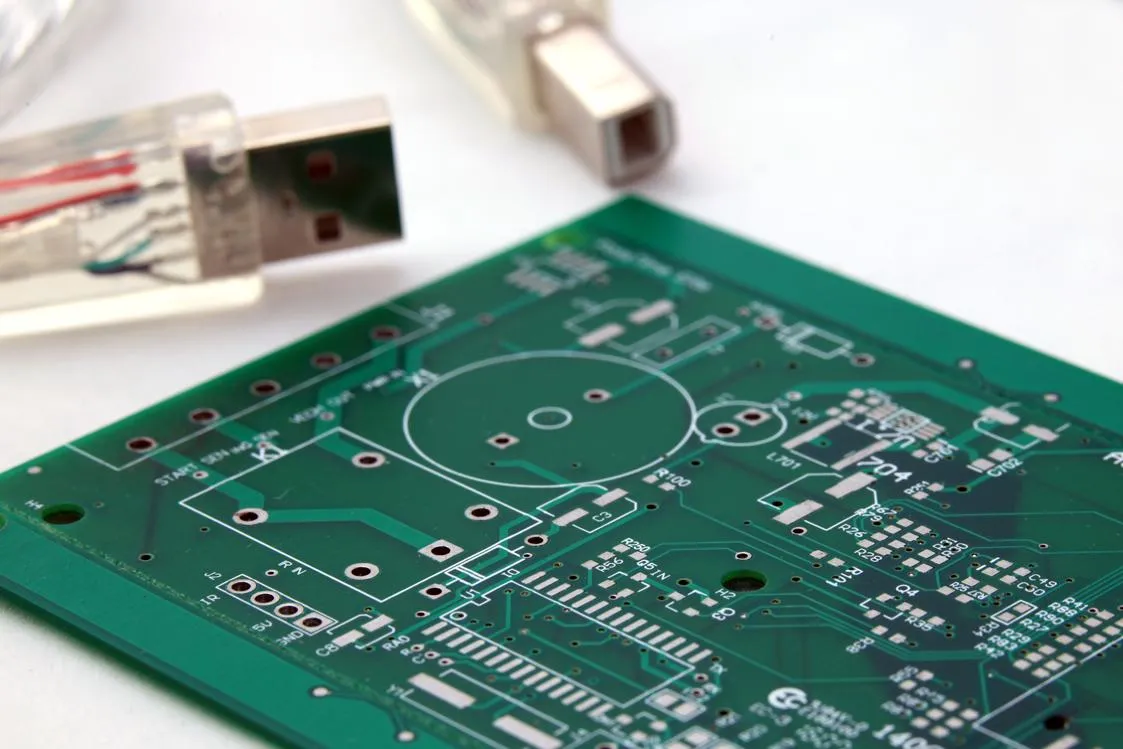

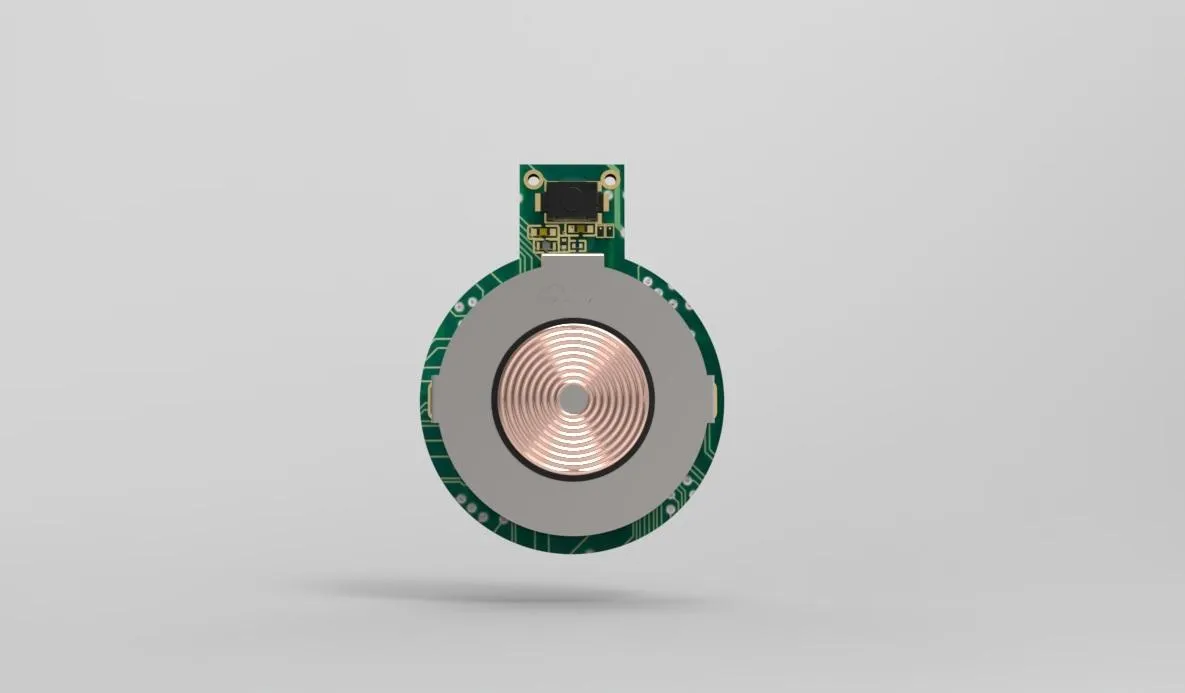

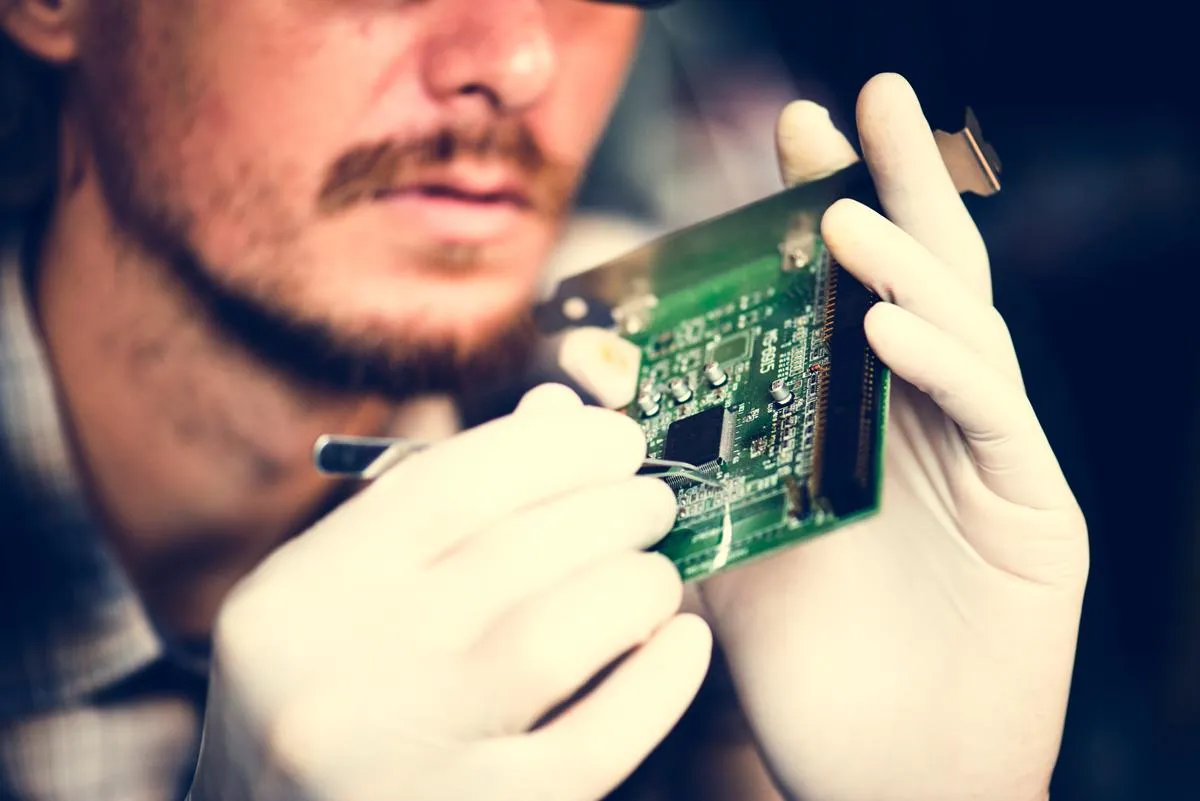

Power Up Your Product

with Expert PCB Design

If your idea involves electronics, this is where it comes to life - intelligently, efficiently,

and ready for prototyping.

You’ve got the concept… but now you need it to function.

Our PCB Development service turns your idea into a real,

functioning brain - starting with requirements gathering and

ending with a refined circuit design and Bill of Materials (BOM).

We don’t just lay out tracks - we help you choose the right components, ensure cost-efficiency, and prepare for seamless prototyping. Every trace, component, and layout choice is

optimized for your needs and your budget.

If your product includes electronics, this step is critical

and we’re here to make it as smooth and smart as possible.

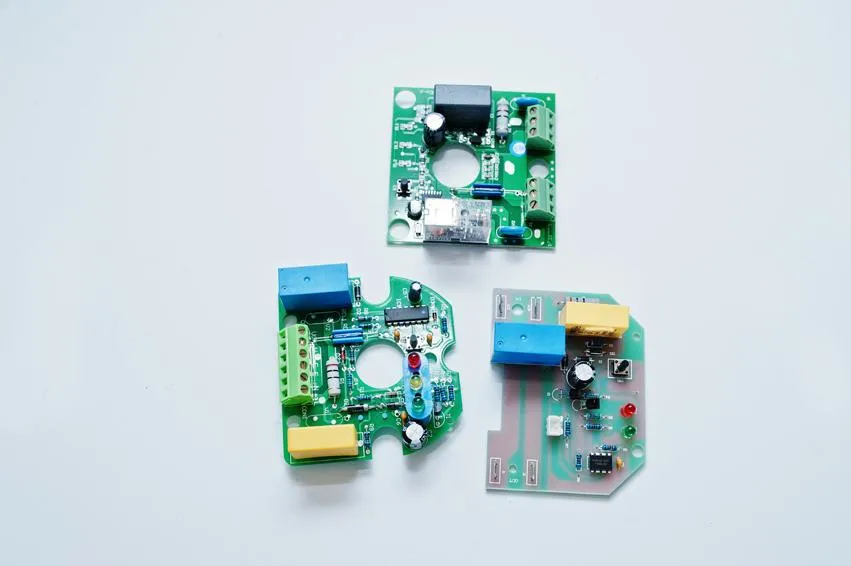

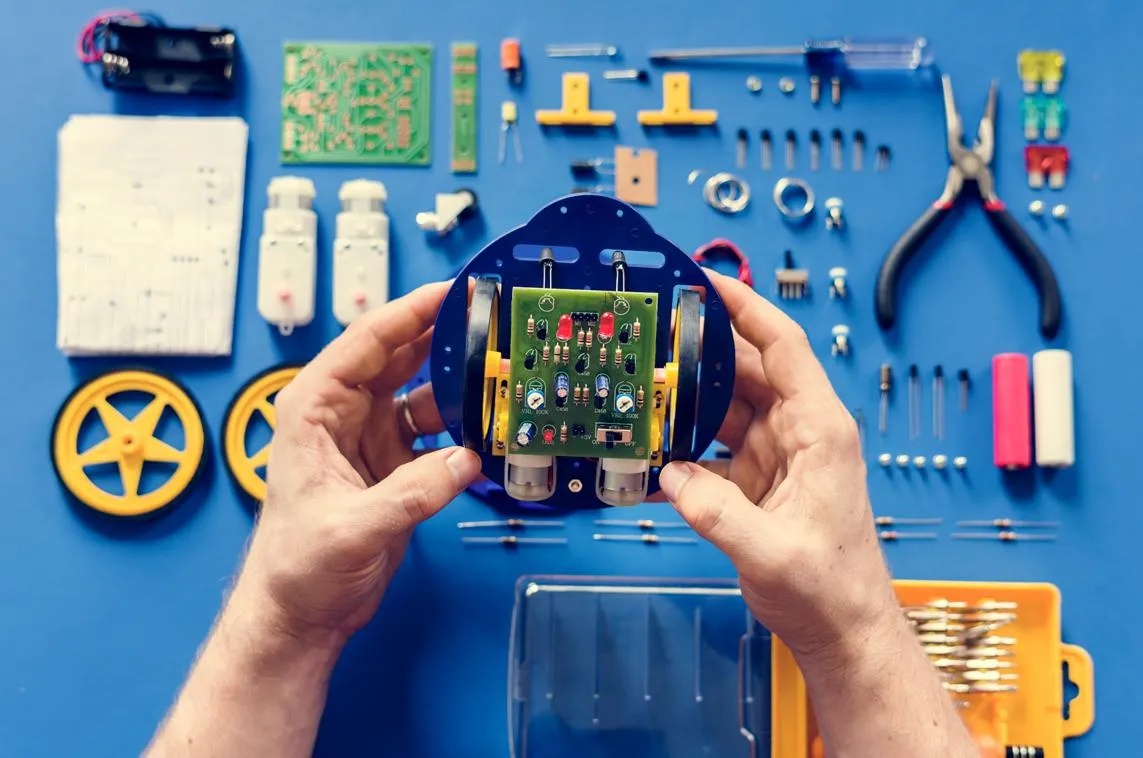

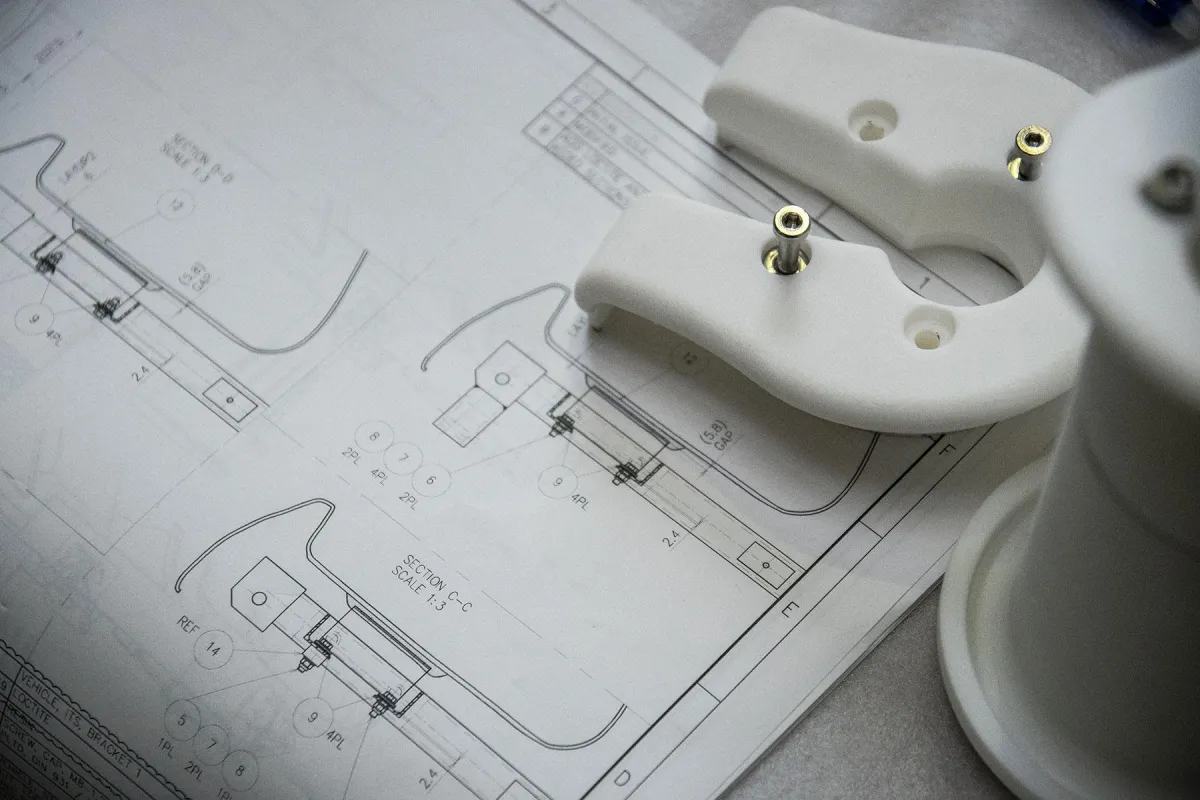

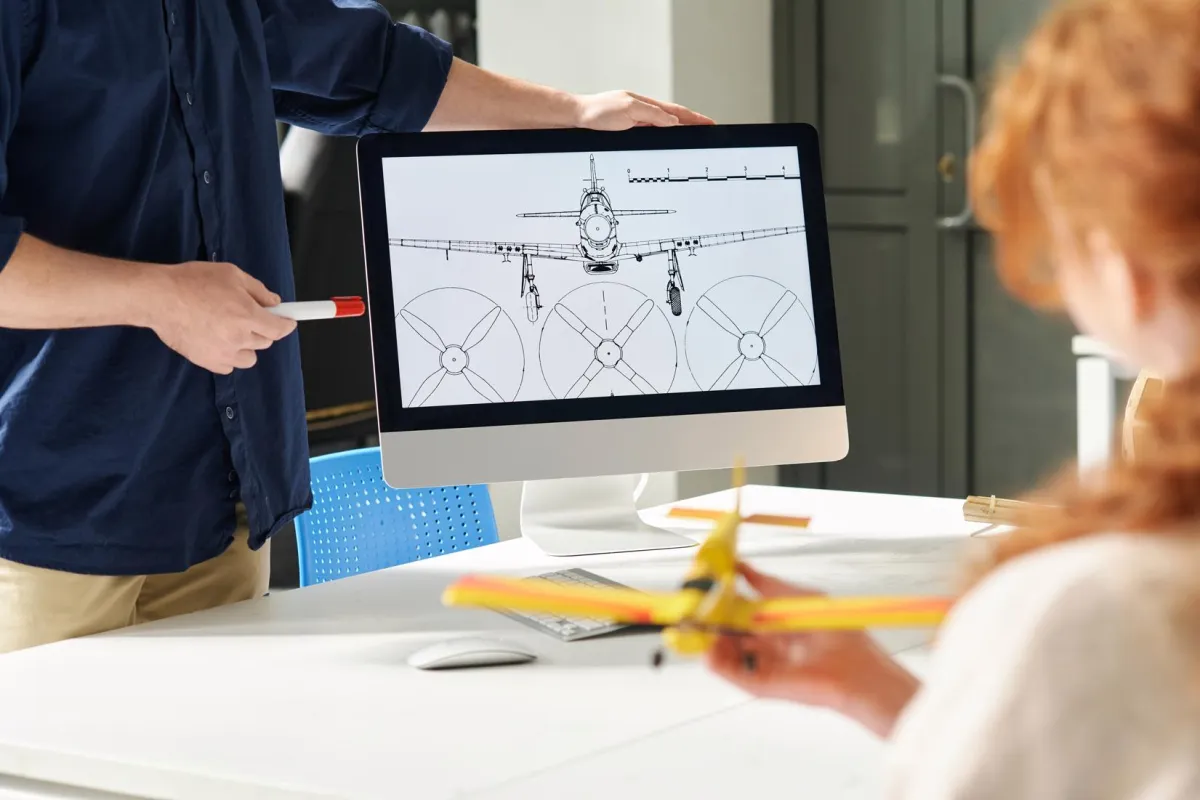

Engineer Every Part

with Precision and Purpose

Turn your concept into an engineered system, with every component and assembly method designed for real-world use.

With your concept now defined and visualized, it’s time to break it down into parts, pieces, and practical mechanics. In this step, we engineer your product for performance, durability, and manufacturability.

We explore assembly options, engineer each component with precision, and build a full 3D assembly ready for prototyping. You’ll receive technical files, exports, and a complete drawing pack that makes building a prototype or moving into production effortless.

This is the bridge between imagination and execution -

the blueprint of your future product.

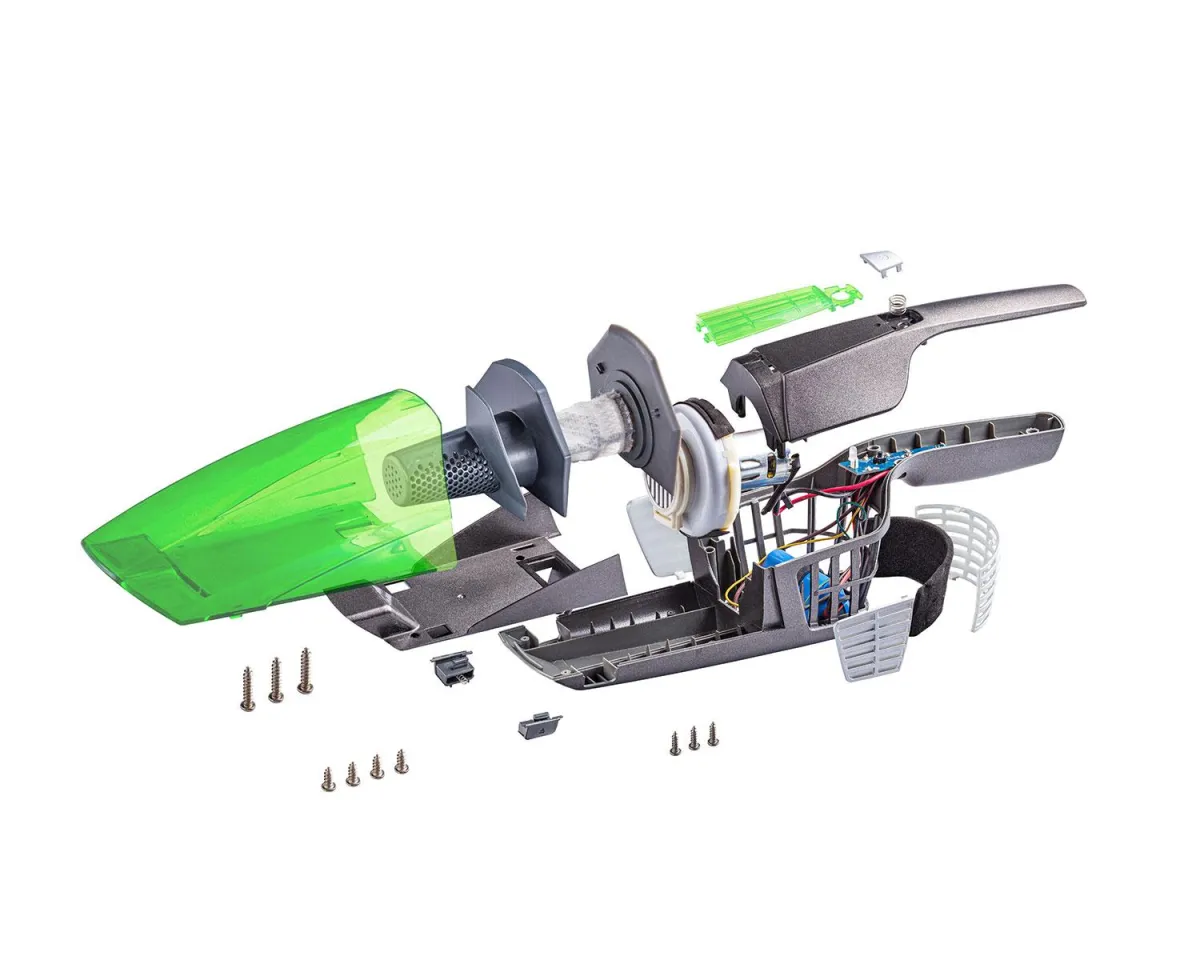

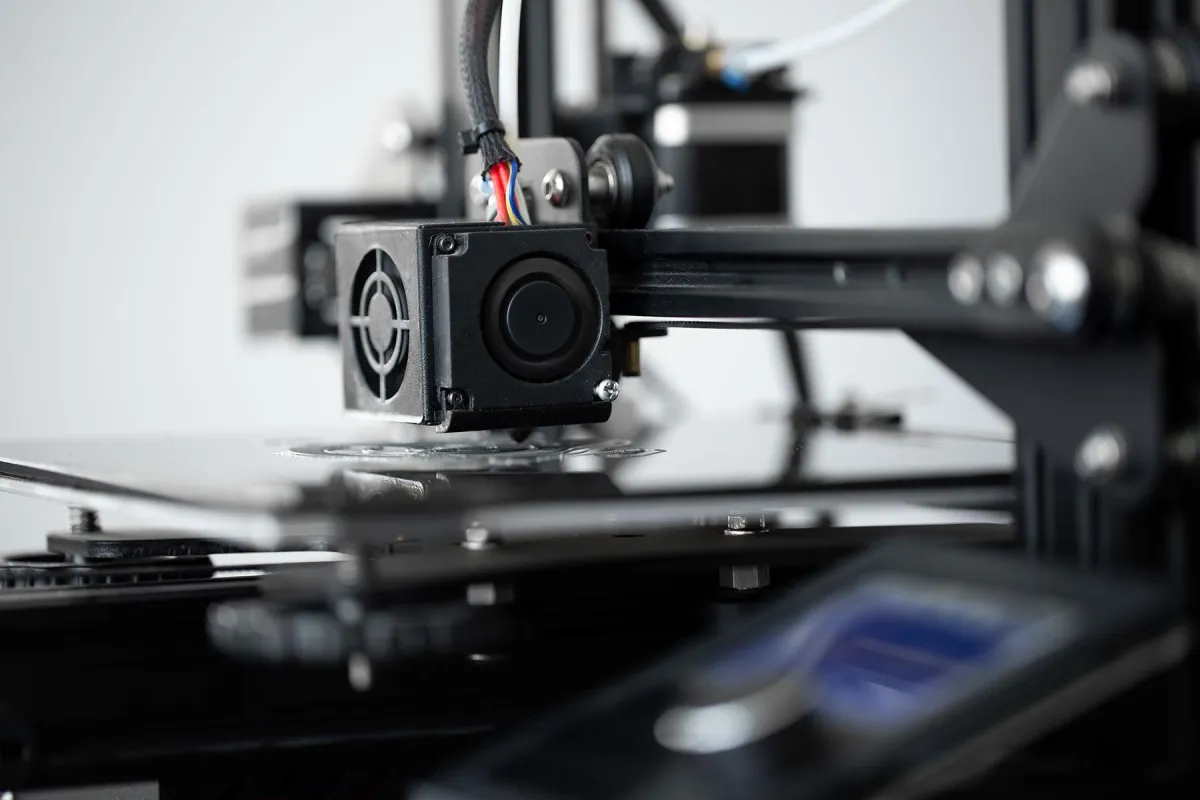

Touch It. Test It. Improve It.

Build and validate your prototype with real materials, reliable quotes, and expert coordination.

You’ve got a brilliant idea—but turning that into something tangible can be overwhelming. Without clarity, your idea stays stuck in sketches or in your head, and you risk going in the wrong direction entirely.

This is where we come in.

In this stage, we help you extract the essence of your idea, explore material and functional possibilities, and develop three unique concept options. Together, we refine one into a stunning 3D model - complete with high-quality renderings so you can see your product in real-

world textures, colors, and finishes.

Whether you're pitching to investors or planning your next move,

Concept Development gives you the visual clarity and strategic foundation you need to move forward.

Everything You Need

Go to Production, all in One Package

Your complete production handoff - 3D models, drawing packs, BOMs, assembly guides,

and ongoing support.

Once your prototype is approved, you need everything in place to begin manufacturing -without guesswork, delays, or missing files.

Our Product Pack gives you everything: STEP & STL models, a full technical drawing pack, Bill of Materials, and clear assembly instructions. We also provide manufacturing guidelines and offer production startup support to help you transition smoothly into

your first run.

Whether you’re handing this to a local supplier or a mass

manufacturer overseas, they’ll have everything they need.

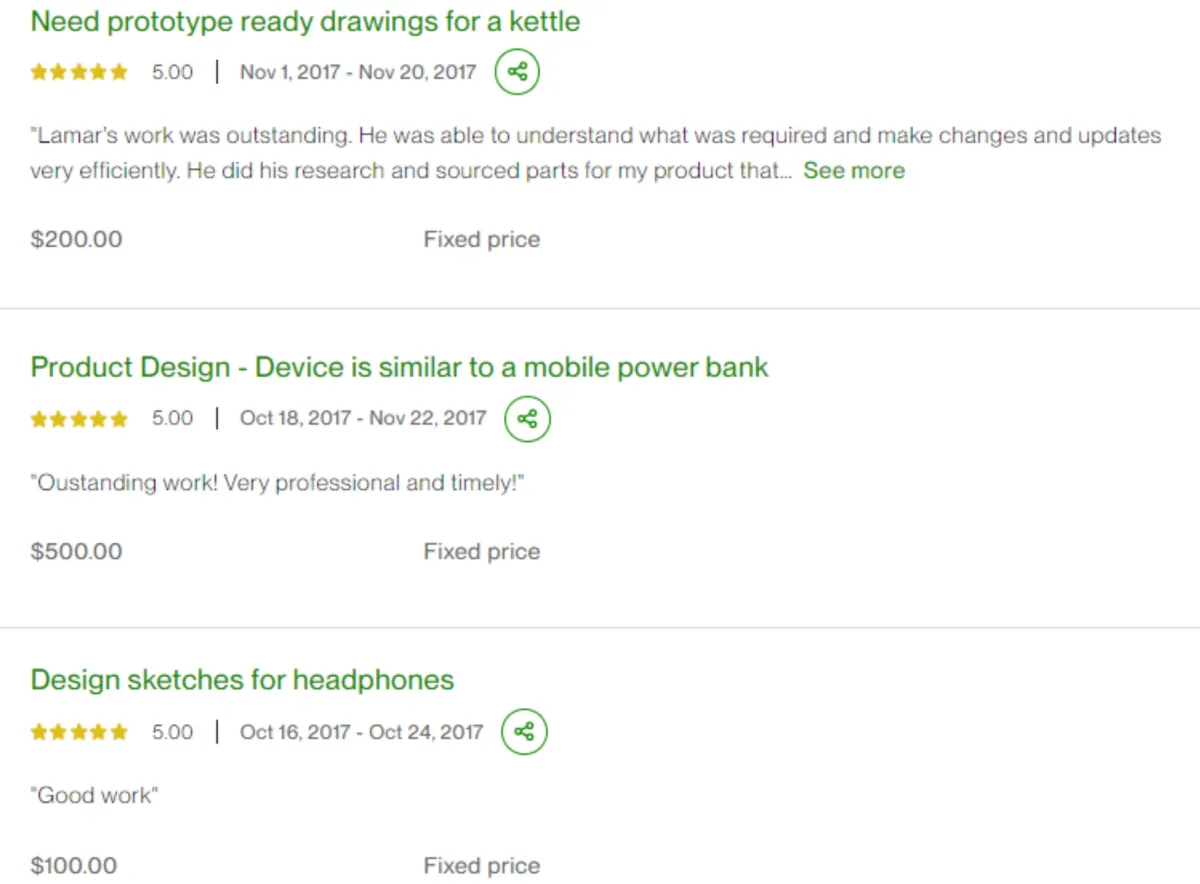

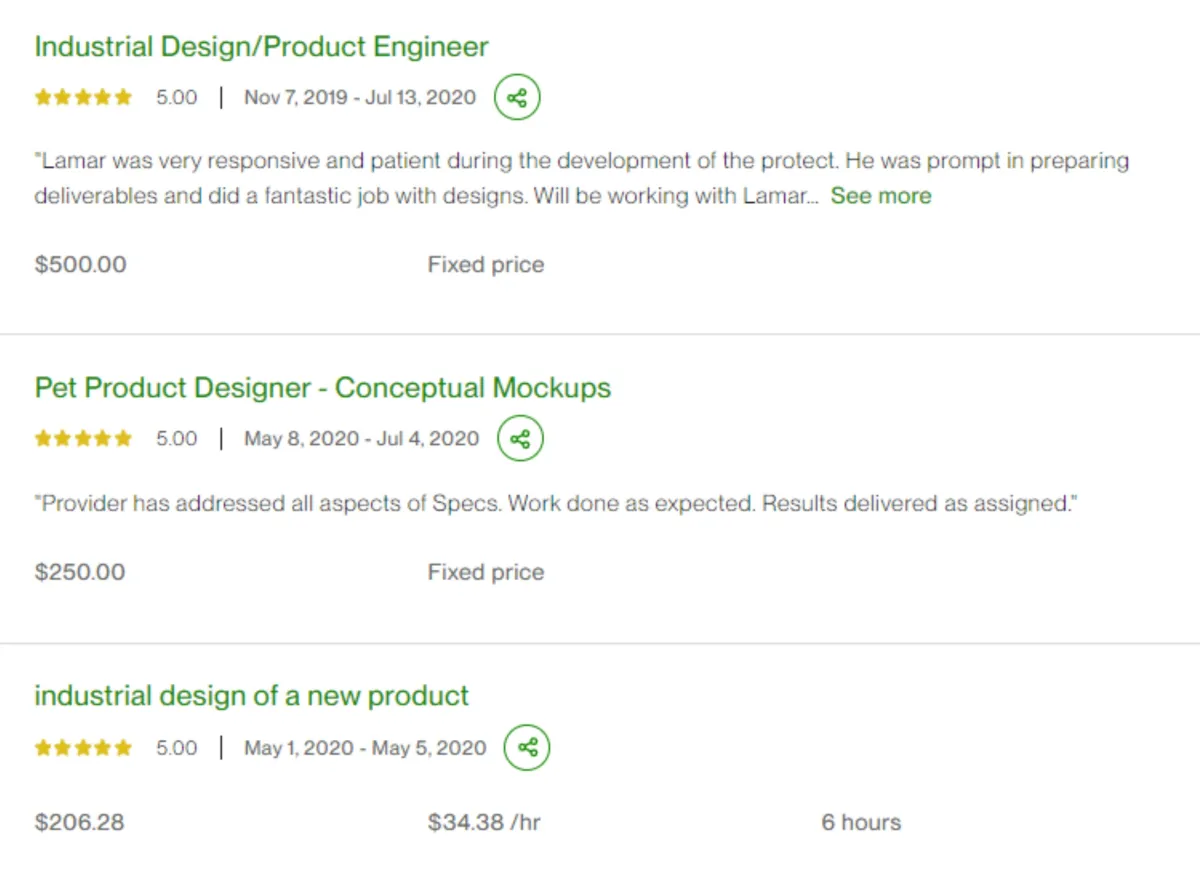

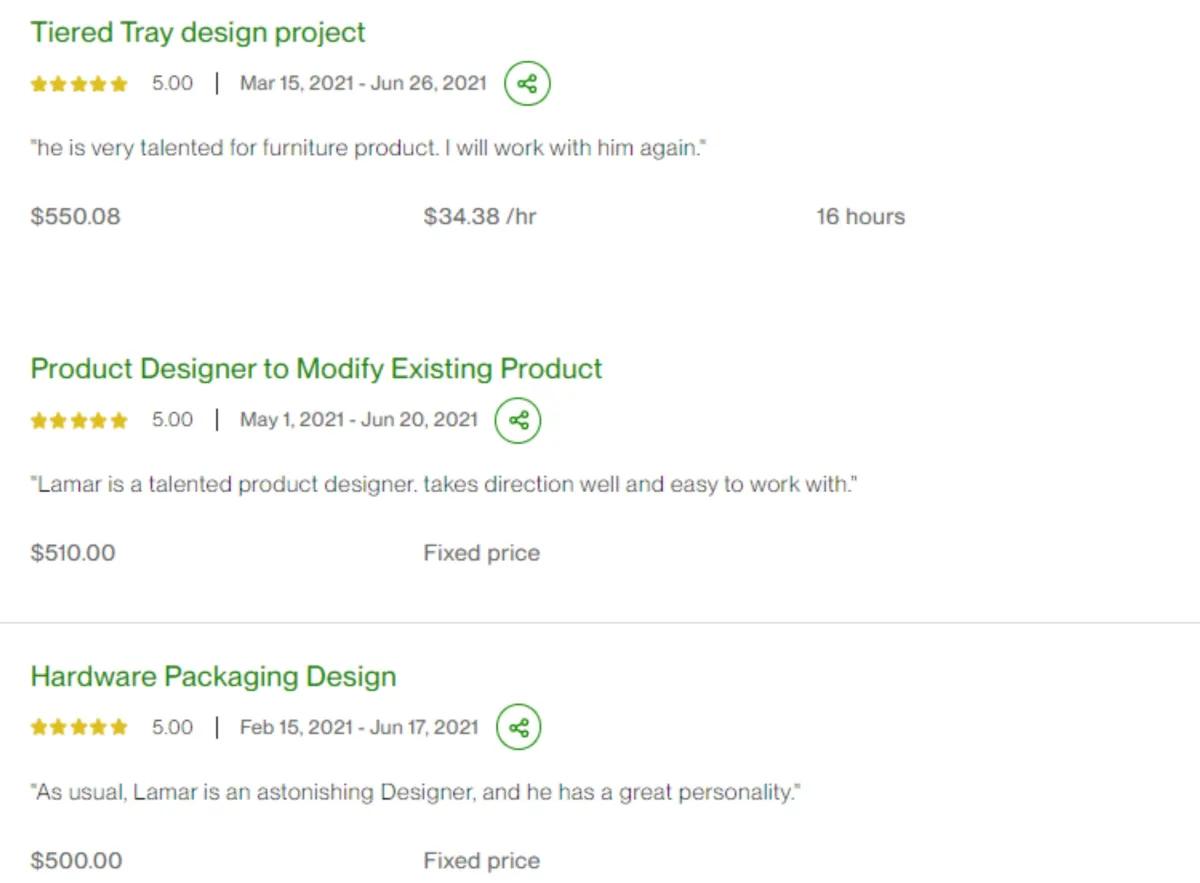

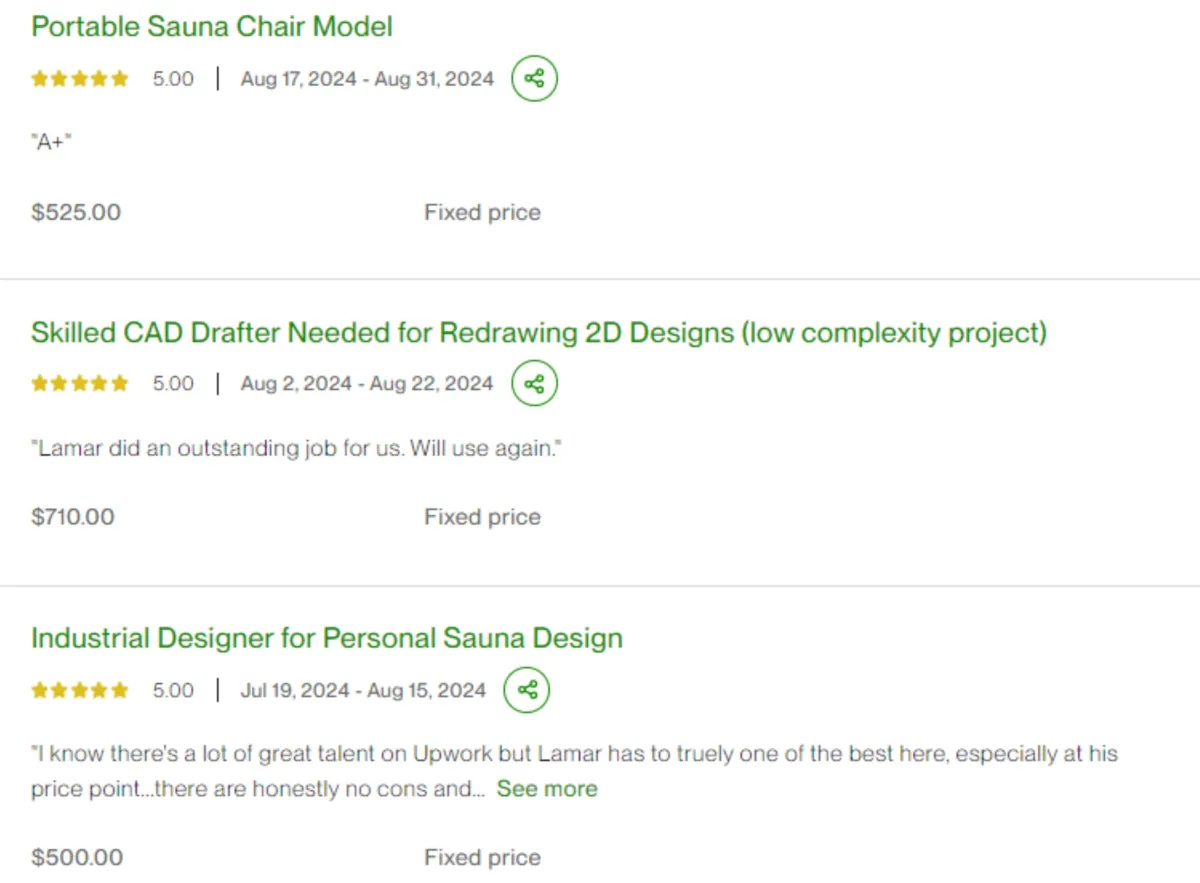

We helped over 500 clients

with 100's of 5 star Reviews!

STILL NOT SURE?

Frequently Asked Questions

Question 1: I only have a rough idea - can I still start?

Yes! You don’t need a perfect sketch or technical drawings to begin. In fact, most of our clients start with just a description or a napkin sketch. Our Concept Development phase is specifically designed to extract, visualize, and explore your idea with professional guidance and visual outputs that bring clarity to your vision.

Question 2: How long does the full process take from concept to prototype?

It depends on the complexity of your product and whether it requires electronics (PCB), but typically the entire process - from concept to working prototype - can take anywhere from 6 to 12 weeks. Each step is modular and paced according to your readiness and involvement.

Question 3: Can I pick only the steps I need, or do I have to do all 5?

Yes, you can choose only the steps you need. Our funnel is designed like a value ladder - each step builds on the previous one, but you're free to start or stop at any point. For example, if you already have a concept but need engineering and prototyping, we can start from Step 3.

Question 4: Do I own the files and designs you create for my project?

Absolutely. Once each stage is completed and paid for, you own all design files, models, drawings, and outputs related to your product. You are free to use them for manufacturing, investor presentations, or marketing.

Question 5: How much will it cost to get my prototype made?

Every product is different, but during the Prototyping phase, we help you gather real supplier quotes and build a costed BOM (Bill of Materials) so there are no surprises. You’re only charged for the actual materials and services required to build your specific prototype - nothing inflated or hidden.

Question 6: What if I need help launching or manufacturing after the prototype?

That’s exactly what our Production Pack is for. We’ll prepare your product for full-scale manufacturing, providing every file, drawing, and guideline a manufacturer will need. We also offer startup production support to help you transition smoothly from prototype to first batch manufacturing.